ASME SECTION 8 PDF CODE

Please note that ASME Code Section 8, does not provide you fabrication tolerances except for misalignment and weld reinforcement.įor example, for nozzle orientation, projection, elevation and other required tolerances there are no values in the code, and you may refer to pressure vessel handbooks for such information. It consists of Parts UCS, UNF, UHA, UCI, UCL, UCD, UHT, ULW, and ULT dealing with carbon and low alloy steels, nonferrous metals, high alloy steels, cast iron, clad and lined material, cast ductile iron, ferritic steels with properties enhanced by heat treatment, layered construction, and low temperature materials, respectively.įor example, if you need to manufacture a pressure vessel with SA 516 Gr.70 material (Carbon Steel), then you need to meet the marked items in above Fig. Subsection C covers specific requirements applicable to the several classes of materials used in pressure vessel construction.

It consists of Parts UW, UF, and UB dealing with welded, forged, and brazed methods, respectively.

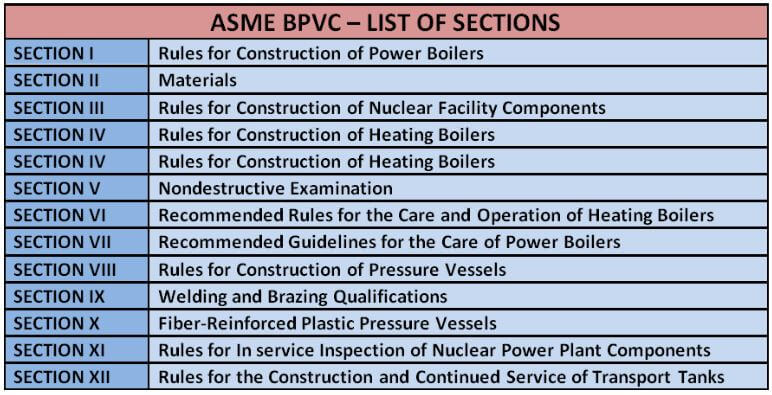

Subsection B covers specific requirements that are applicable to the various methods used in the fabrication of pressure vessels. Subsection A consists of Part UG, covering the general requirements applicable to all pressure vessels. This section is divided into three Subsections, Mandatory Appendices, and Nonmandatory Appendices. See following Fig it shows ASME Code Section 8 Content: We have assigned a separate article for the NBIC, but as required for this article, the NBIC is making certification for ASME Authorized Inspectors and is also certifying R stamp for Repair services for stamped pressure vessels. The ASME Section VI for the heating boiler and Section VII are from this group. These are the codes for in-service inspection after placing the equipment into service. The ASME Section IX for welding and Section V for Non Destructive Testing are in this Group.įor example, ASME Code section VIII for welding requirement such as WPS (Welding Procedure Specification), PQR (Procedure Qualification Record), Welder Performance Qualification, etc. These are the codes which are referenced from construction codes as explained in group 1. Some of them are: Section VIII for pressure vessel, Section I for Power Boiler, section III for Nuclear Power Plant and Section IV for heating Boiler The next item in this hierarchy is ASME Code itself the ASME Code generally is divided into three groups as following: The ASME Training Course is 5 days video training course and available online and the student that successfully pass the exam, receive I4I academy certificate with 40 hours training credit. Mandatory application of ASME pressure vessel code is determined by rule and regulation at location of installation.įor example, if you are living in the state of Minnesota, the application of ASME Code for construction and stamping is mandatory in your location, but if you are living in the state of South Carolina, it is not mandatory. Law and Regulation at Location of Installation ASME Code Section 8 - Hierarchy of Standardġ. Division 1 covers pressure up to 3000 psi, Division 2 has an alternative rule and covers up to 10,000 psi and Division 3 can be used for pressure higher than 10,000 psi.

You may know ASME Code Section 8 has three divisions.

0 kommentar(er)

0 kommentar(er)